Titan Industries e-Catalogue

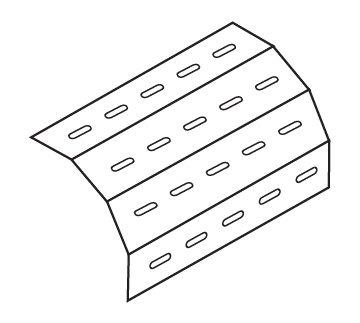

Cable Tray Systems

Cable Tray Systems-

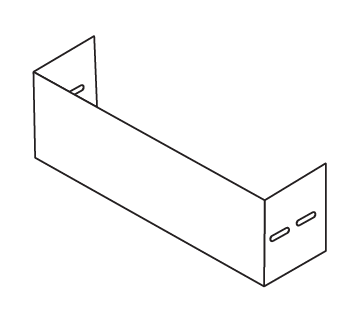

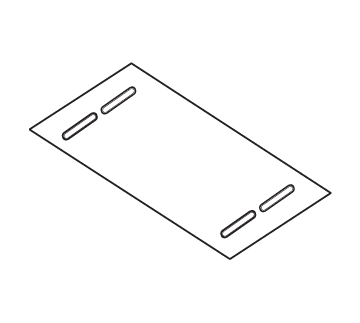

Cable Trunking Systems

Cable Trunking Systems -

Cable Ladder Systems

Cable Ladder Systems -

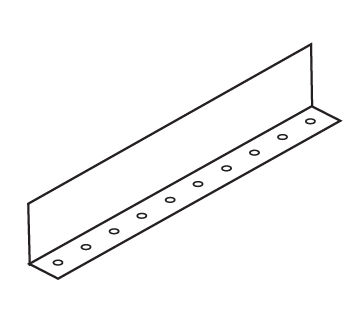

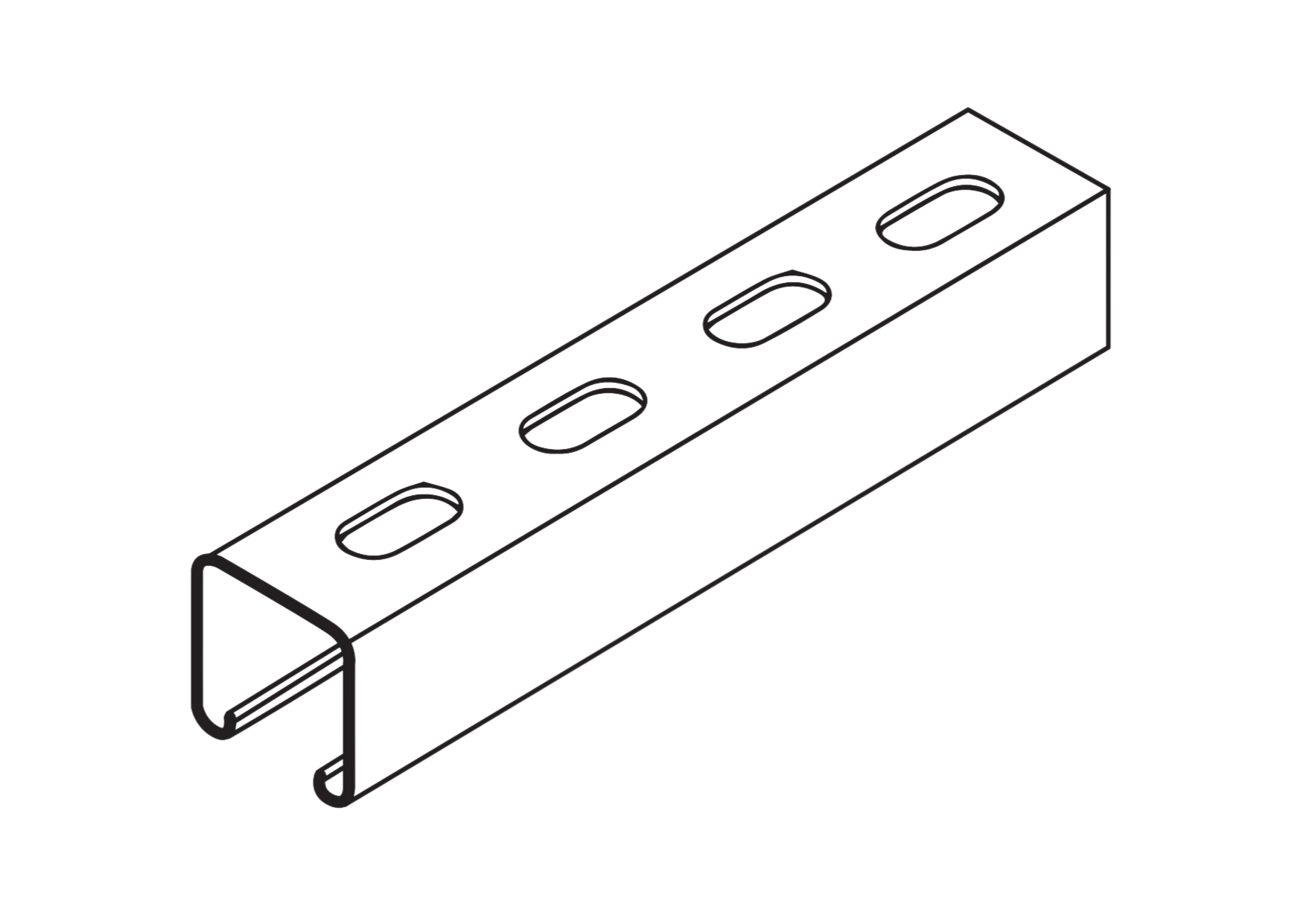

Channel Support Systems

Channel Support Systems -

Pipe Clamping Systems

Pipe Clamping Systems -

Finishes for Cable Management Systems

Finishes for Cable Management Systems

Home Our Products

Cable Tray Systems

Cable Tray Systems Cable Trunking Systems

Cable Trunking Systems Cable Ladder Systems

Cable Ladder Systems Channel Support Systems

Channel Support Systems Pipe Clamping Systems

Pipe Clamping Systems Finishes for Cable Management Systems

Finishes for Cable Management Systems

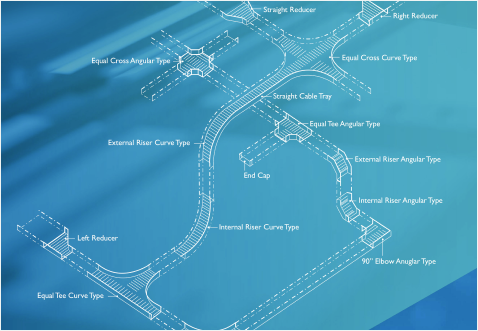

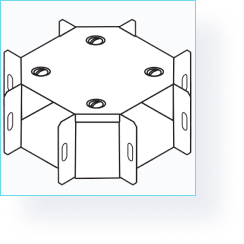

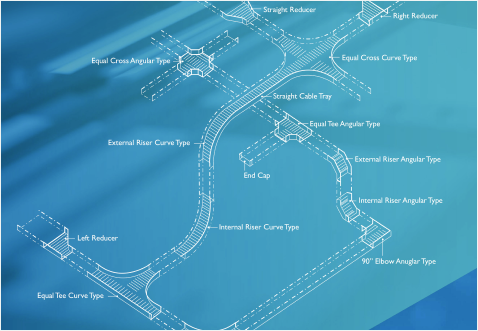

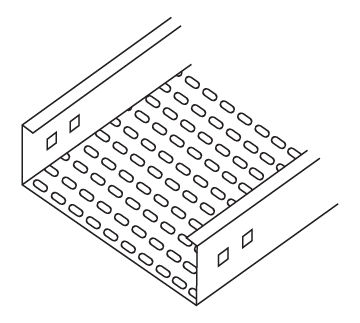

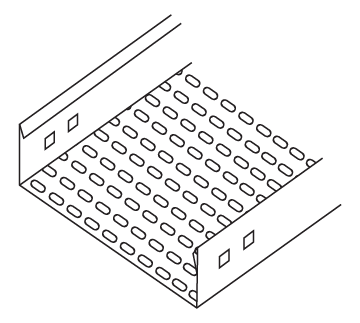

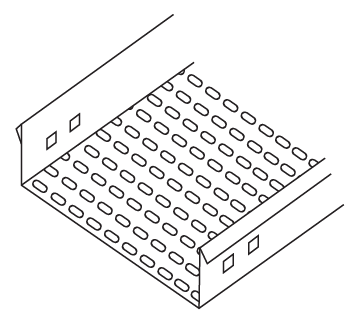

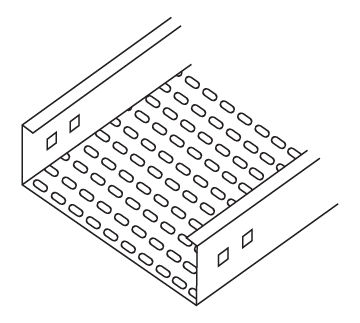

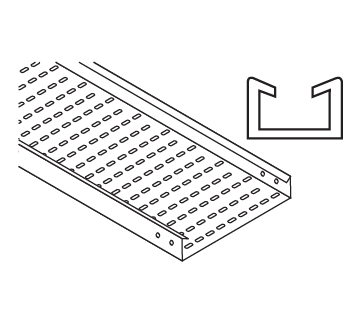

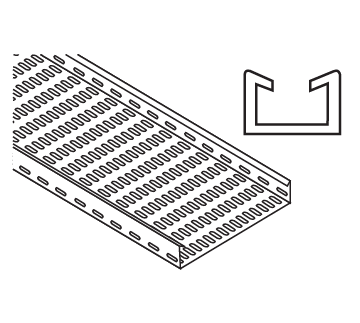

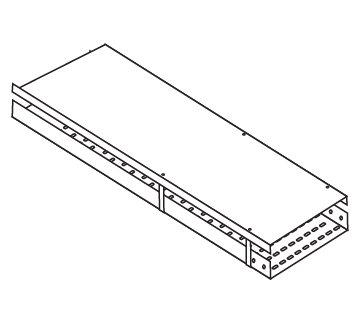

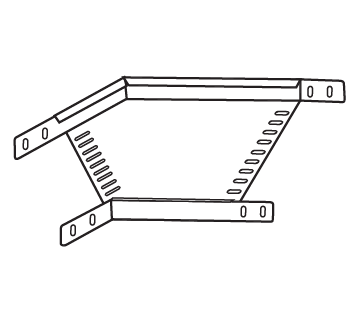

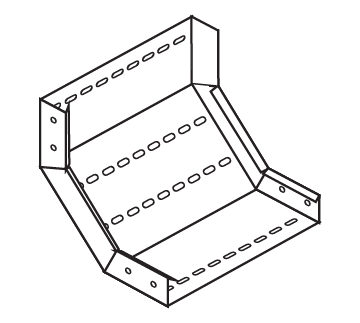

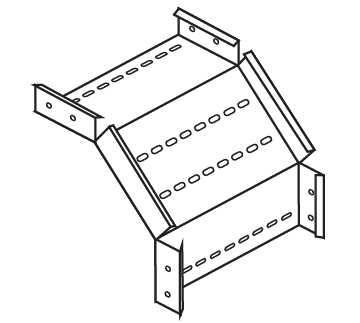

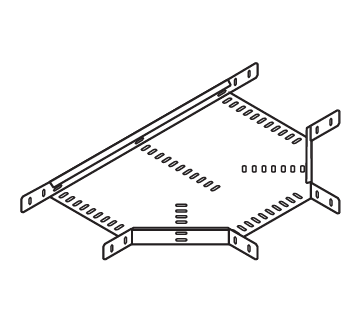

A comprehensive range of steel and aluminium cable trays and accessories suitable for a variety of industrial and commercial cable support requirements. With speed of installations and cost-saving in mind all systems are manufactured to comply with International standards.

Perforated Cable Tray

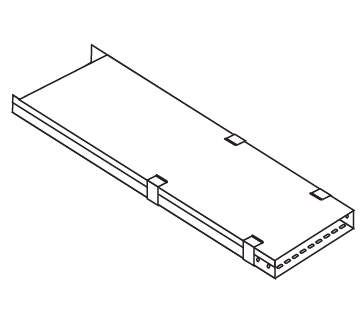

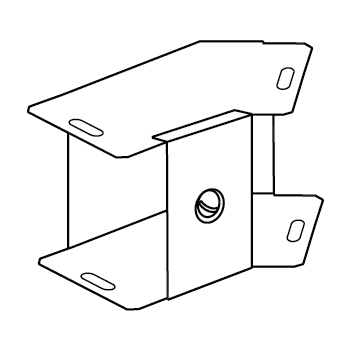

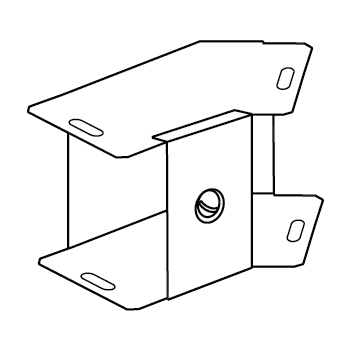

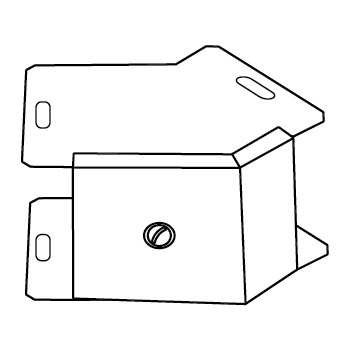

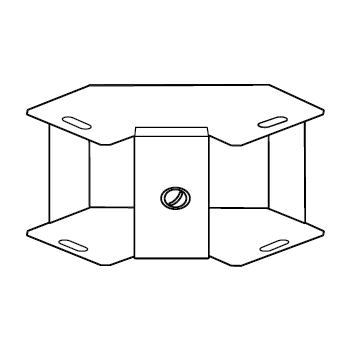

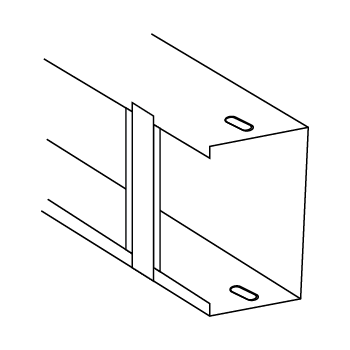

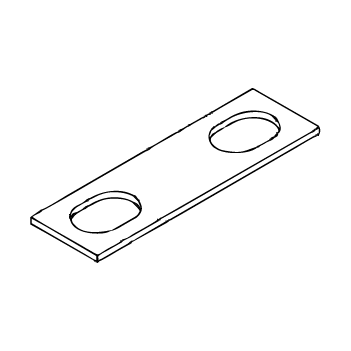

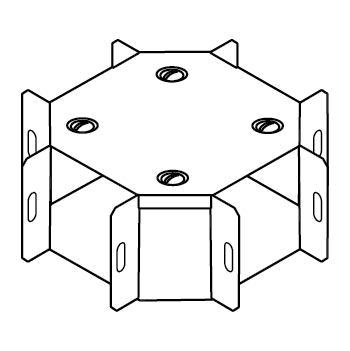

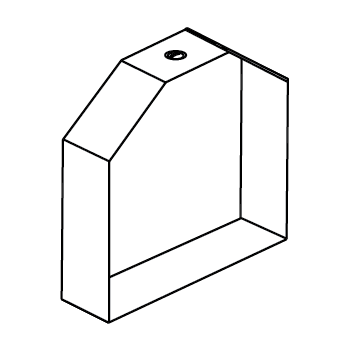

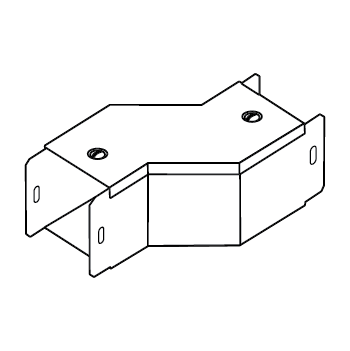

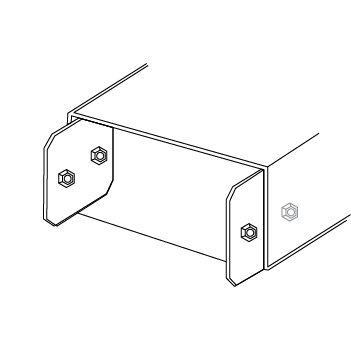

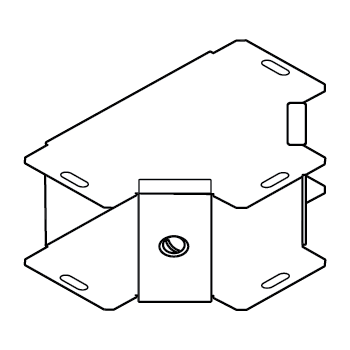

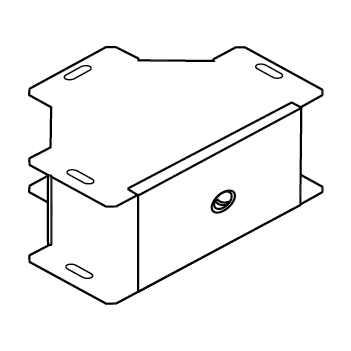

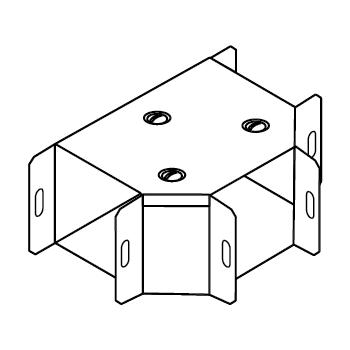

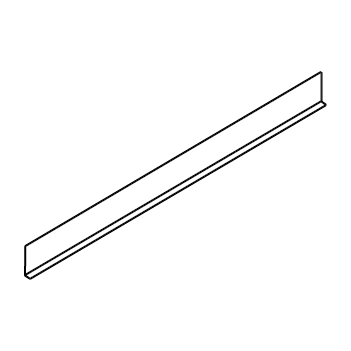

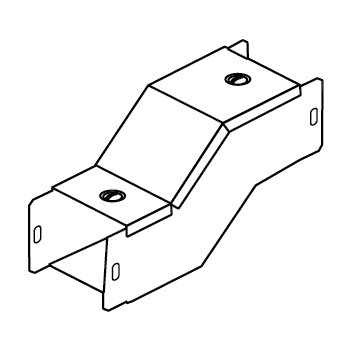

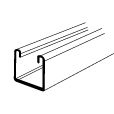

Steel Surface Cable Trunking and fittings are designed and manufactured to comply with BS 4678:Part 1. Trunking is manufactured in single or multi-compartment versions of 2.44 and 3 meter lengths. The smooth return edges increase strength and rigidity and the trunking is supplied with lid, coupler and screws.

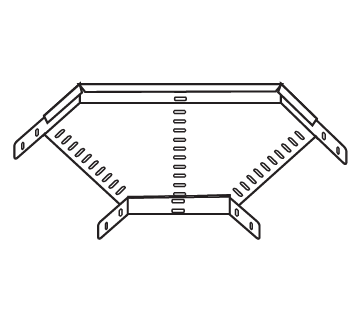

Metal cable ladders and fittings are designed to accommodate heavy duty power distribution cables within industrial buildings. The system has high load carrying capabilities, is simple to install and is available with a full range of accessories.

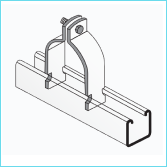

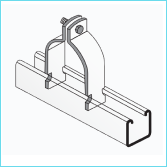

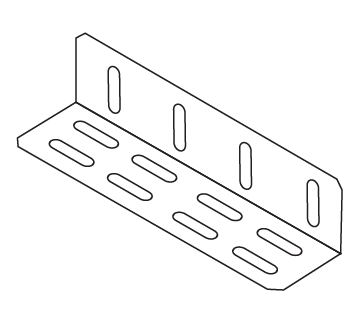

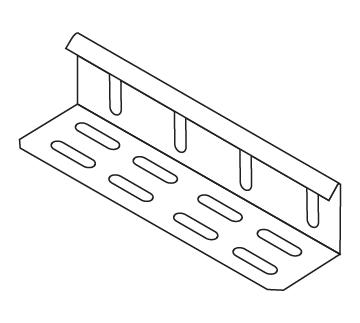

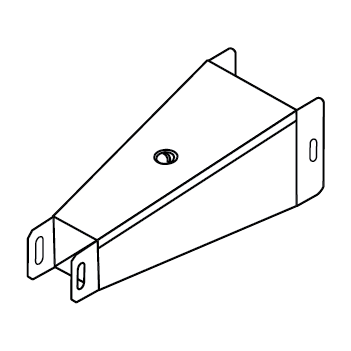

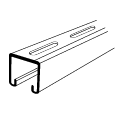

Metal cable channels and fittings are designed to hold a maximum load. Metal Channels and concrete inserts can be manufactured to client specification and are available in 2.9 metre, 3 metre and 6 metre lengths. Support systems include cantilever arms, support brackets and base post supports respectively.

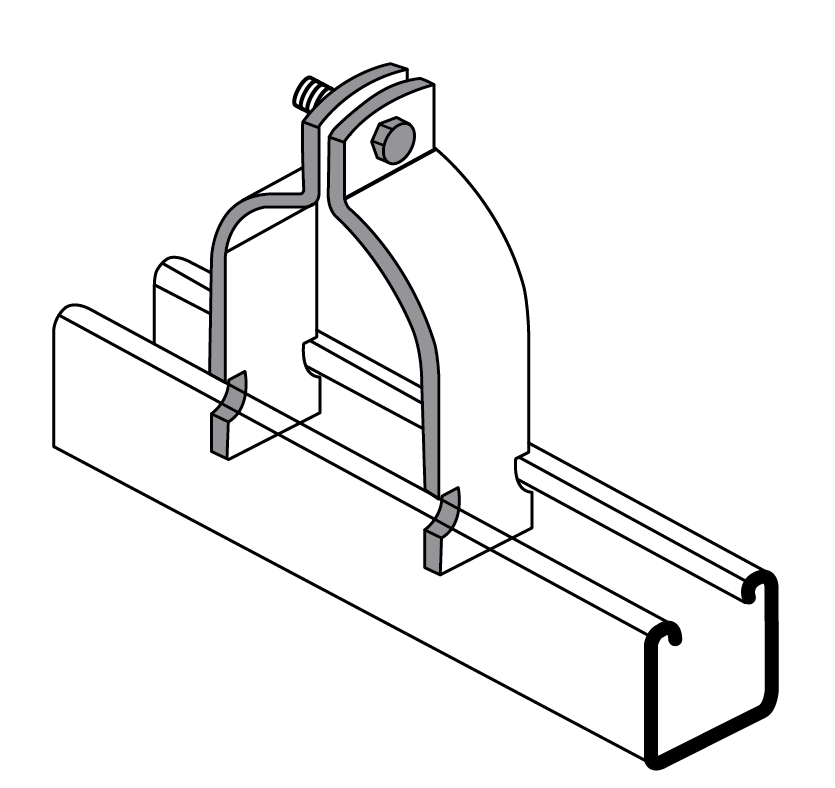

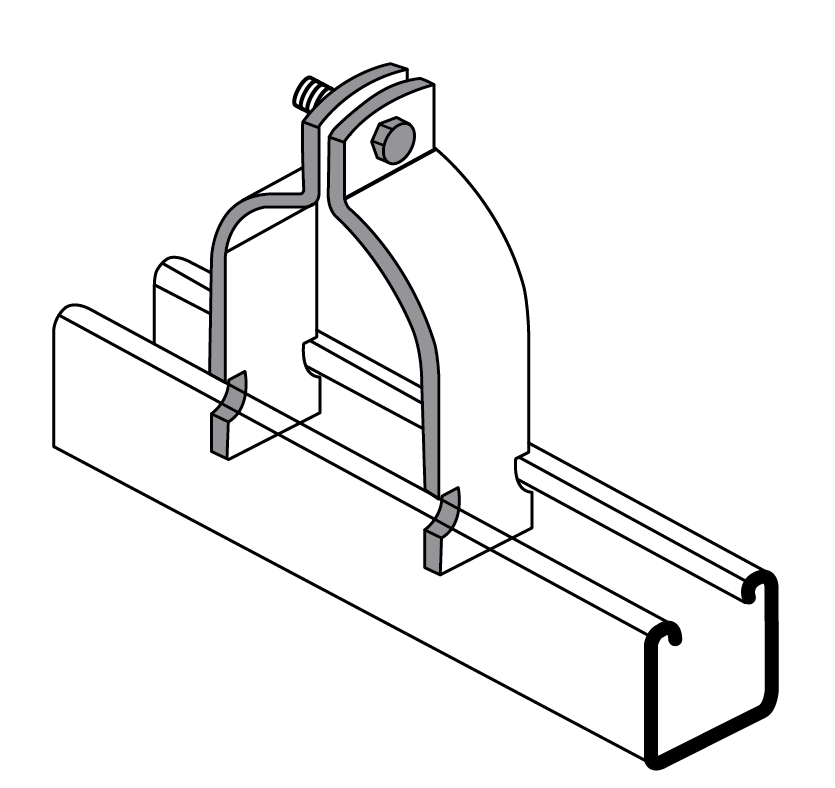

The Pipe Clamps manufactured by Titan Industries are suitable for the fixing of light to heavy channel system and to support a wide variety of pipe sizes.

Our products are available in the following finishes: Pre-Galvanized Steel (PG), Hot Dip Galvanized Steel (HDG), Stainless Steel (SS) and Epoxy Powder Coating.

Mild steel is treated in an uninterrupted operation while it is still in the coil form to clean the steel and passed through a bath of molten zinc to form a Zinc/Iron alloy. As the steel is cooled, a coating of pure zinc will form on the steel and its then re coiled. It is then cut to length and formed with the advantage of the steel already being galvanized. The Zinc will be able to offer an electro-chemical protection even at unprotected edges which is why the coating is not allowed to become thick due to the chance of splitting during the forming process.

After the forming, manufacturing and finally cleaning process of the product in mild steel is completed, the final product will be submerged in a bath of molten zinc hence making sure that the whole product is coated with a thick layer of zinc. Due to this process, products with a HDG finish will have a thicker coating of zinc as opposed to the PG finish. Surface distortion and coarseness will be evident but it does not hamper the technical qualities of the product in any manner as it is just a byproduct of the hot working process.

Stainless Steel contains an alloy of iron with varying levels of other elements such as Chromium, Carbon, and Nickel etc. which prevents corrosion of the surface by forming a thin layer of oxide on the surface and thus reducing the rate at which iron will oxidize. Stain-less steel should not be misunderstood for stain-impossible as pollutants and chemicals will eventually stain the surface but it will not deteriorate the strength of the steel. In more aggressive conditions, the basic type of stainless steel may corrode. In such cases, stainless steel that are highly alloyed can be used.

These coatings are primarily used for aesthetic requirements and is particularly useful to identify the type of cabling running through the different types of cable management. They are available in a variety of colours and can be standardized in a project by using the RAL codes to identify the different types of colours required thus enhancing the architectural requirements.

Information you shared was successfully submitted. Thank you, we'll get back to you soon!

Thank you for showing interest in our products.

We'll be in touch.

| Code | Side Height | Width of trays | |||

|---|---|---|---|---|---|

| LD | MD | HD | EHD | ||

| TCM/R/AT-1 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-2 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-3 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-4 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-5 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-6 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-7 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-8 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-9 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-10 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

| TCM/R/AT-11 | 15 | 25 | 50 | 100 | 50, 75, 100, 150, 225, 300, 450, 600, 750, 900, 1000 |

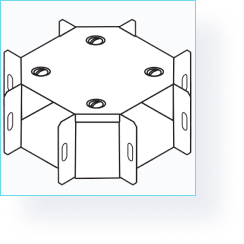

| Code | Accessory Type | Reference | Width of the trays |

|---|---|---|---|

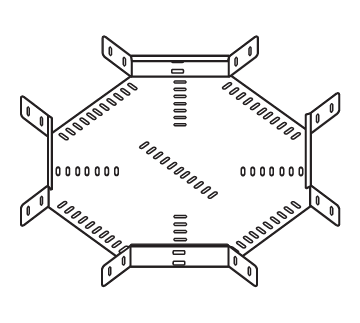

| TCM/TYPE-A | Cable Trunking 90 Deg Top Open Bend | TCM/TYPE-J | Cable Trunking Equal Cross |

| TCM/TYPE-B | Cable Trunking 45 Deg Top Open Bend | TCM/TYPE-K | Cable Trunking Vertical Offset |

| TCM/TYPE-C | Cable Trunking 90 Deg Inside Open Bend | TCM/TYPE-L | Cable Trunking Horizontal offset |

| TCM/TYPE-D | Cable Trunking 45 Deg Inside Open Bend | TCM/TYPE-M | Cable Trunking Reducer |

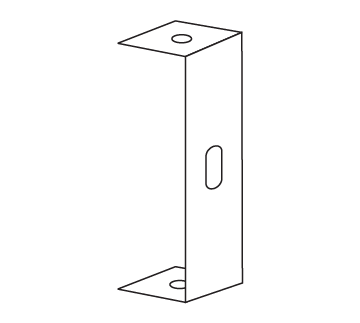

| TCM/TYPE-E | Cable Trunking 90 Deg Outside Open Bend | TCM/TYPE-N | Cable Trunking Hanger Bracket |

| TCM/TYPE-F | Cable Trunking 45 Deg Outside Open Bend | TCM/R/TD | Cable Trunking Divider |

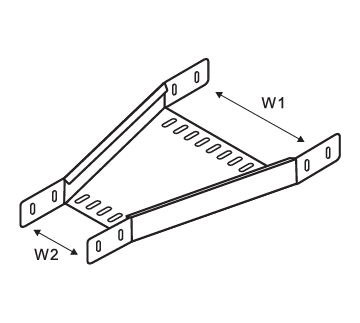

| TCM/TYPE-G | Cable Trunking Tee Top Open Bend | TCM/R/EL | Cable Trunking Earth Link |

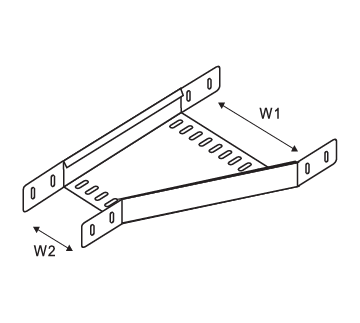

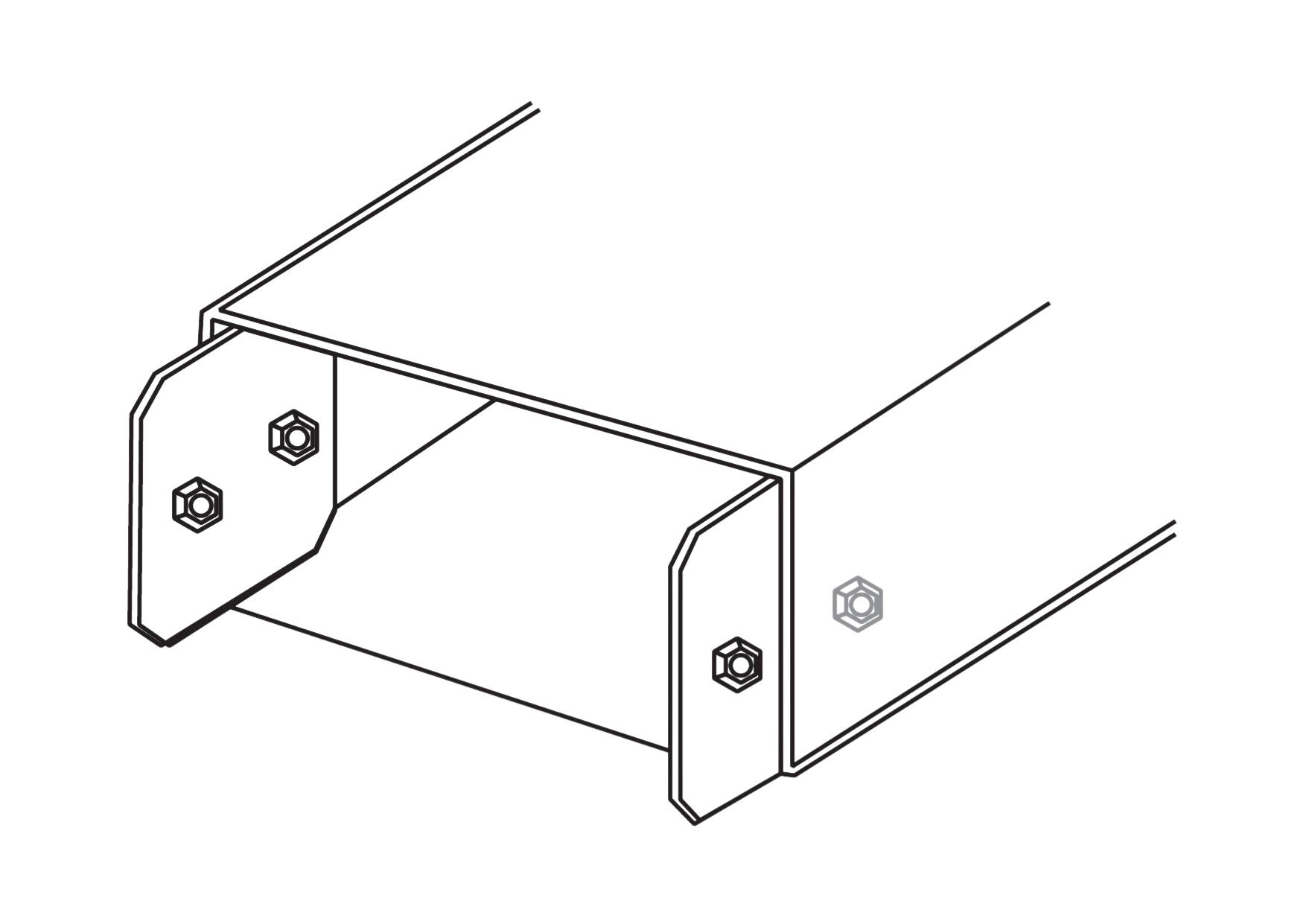

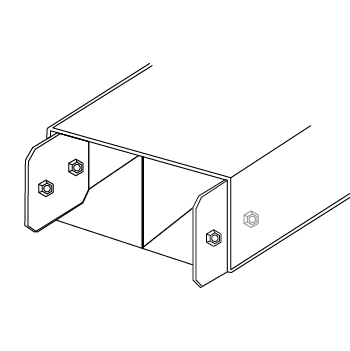

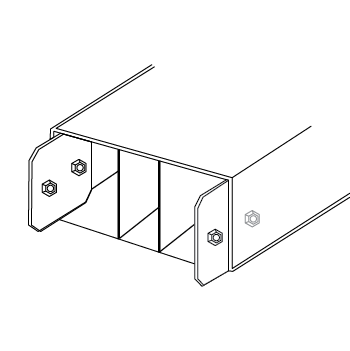

| TCM/TYPE-H | Cable Trunking Tee Inside Open Bend | TCM/JC | Cable Trunking Joint Coupler |

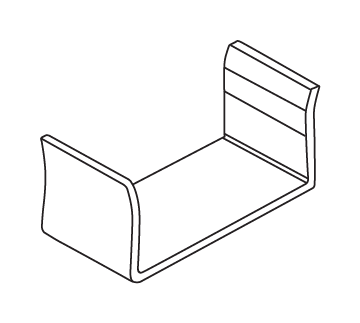

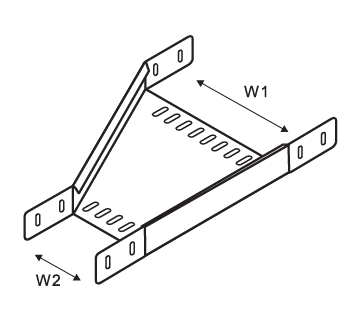

| TCM/TYPE-I | Cable Trunking Tee Outside Open Bend | TCM/CR | Cable Trunking Cable Retainer |

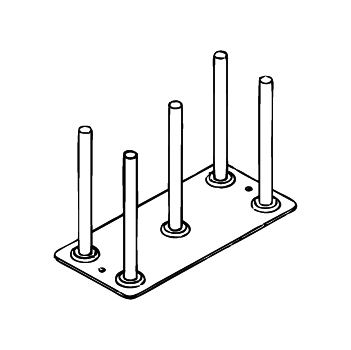

| TCM/PR | Cable Trunking Pin Rack |

| Code | Height | Width | Thickness | Length | |

|---|---|---|---|---|---|

| TCM/ST/22 | 50 | 50 | 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/32 | 75 | 50 | 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/33 | 75 | 75 | 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/42 | 100 | 50 | 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/43 | 100 | 75 | 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/44 | 100 | 100 | 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/62 | 150 | 50 | 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/63 | 150 | 75 | 1, 1.2, 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/64 | 150 | 100 | 1, 1.2, 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/66 | 50 | 50 | 0.5, 0.6, 0.7, 0.8, 0.9, 1, 1.2, 1.5, 2mm | 2.44M/L | 3M/L |

| TCM/ST/82 | 150 | 150 | 1, 1.2, 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/83 | 200 | 50 | 1.2, 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/84 | 200 | 75 | 1.2, 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/122 | 300 | 50 | 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/123 | 300 | 75 | 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| TCM/ST/124 | 300 | 100 | 1.5, 2, 2.5mm | 2.44M/L | 3M/L |

| Part No. | Size (mm) | Part No. | Size (mm) | Part No. | Size (mm) | Part No. | Part No. |

|---|---|---|---|---|---|---|---|

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

| TCM1101 | 8.7 : 10.3 | TCM1113 | 31.8 : 35.9 | TCM1125 | 82.6 : 88.1 | TCM1137 | 182.6 : 190.5 |

Thank you for showing interest in our products.

We'll be in touch.